Еlaboration of tape-casting technique for ceramic fuel cell production

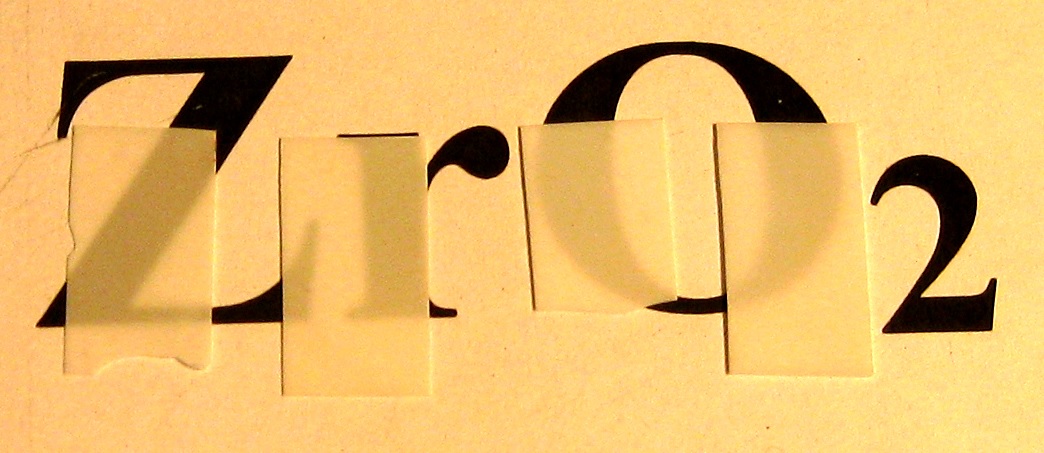

Fig. 1 - SOFC electrolyte films of different thikness made of zirconia stabilized

with 8-mol.% yttria powder (8YSZ) developed newly.

|

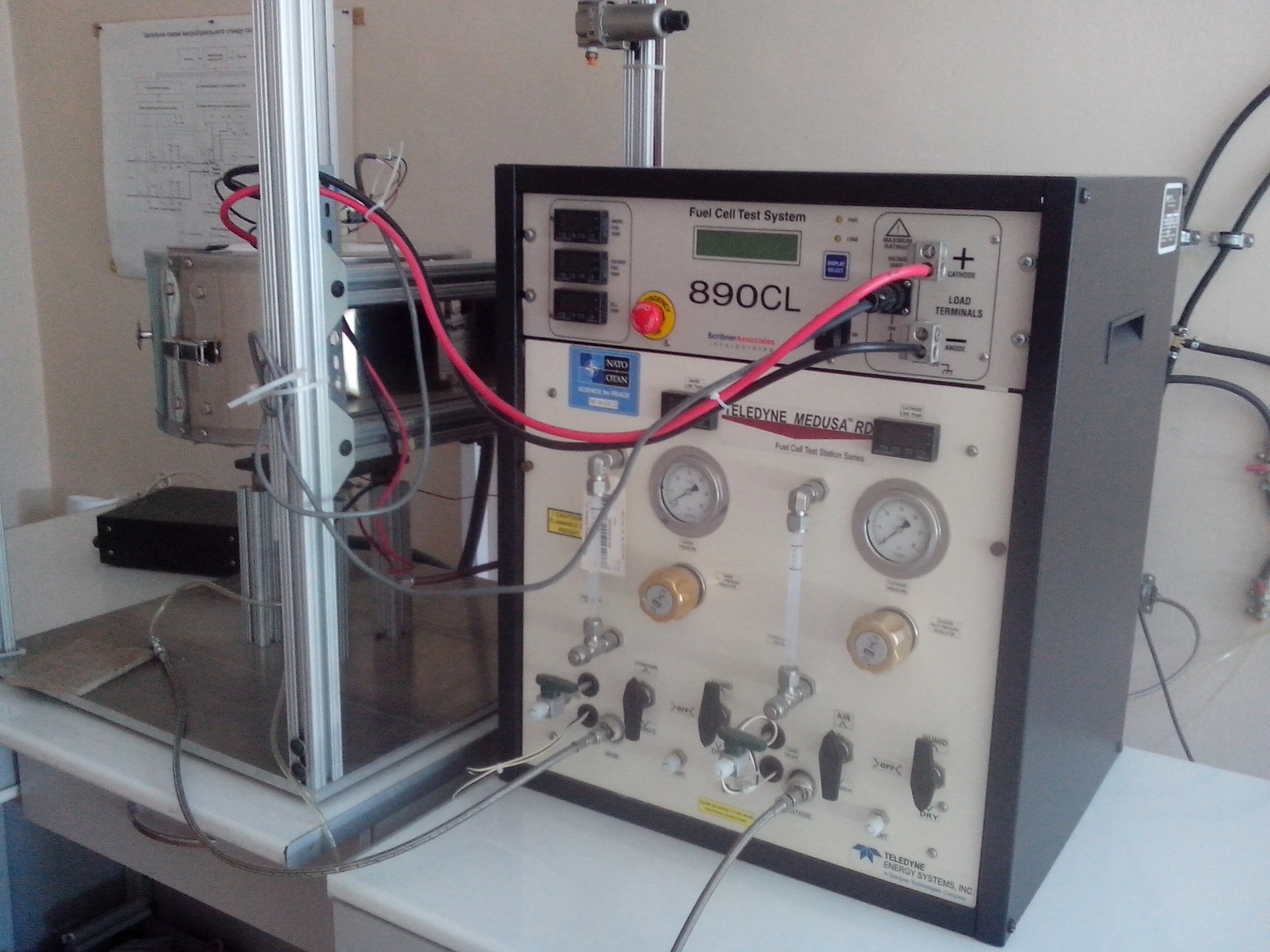

Fig. 2 Appliance for fuel cell testing – Scribner Teledyne Medusa RD 890CL

|

Fig. 3 Appliance for hydrogen production by Hydrogen Kengo-Digital 15.50

|

Area of application

Typically, solid oxide fuel cells (SOFCs) are used as stationary power equipment for decentralized energy supply.

SOFCs are considered to be the most promising among other types of fuel cells for widespread application due to their

high efficiency of fuel chemical energy conversion of into electrical and heat ones, fuel flexibility (methane, hydrogen, CO etc.);

they do not need in platinum group metals as catalysts. Owing to the modularity of fuel cells, power sources based on fuel cells can

be principally of any capacity (from microwatts to megawatts) and optimized for any application.

Brief description

The general research plan foresees elaboration of regimes for the manufacturing of SOFC using tape-casting technique, structure

optimization of electrolyte and electrodes, choosing of optimal modes of SOFC operation and development of the operational suitability

of cells to be used in the energy-generating stacks. The structure optimization of electrolyte consists of the development of new electrolyte

material based on zirconia stabilized with complex dopants Y2O3, Sc2O3, CeO2 (YScCeSZ). The choosing of SOFC operation modes includes the

study of the influence of different fuels (hydrogen, carbon monoxide, methane, and syn-gas), their flows and concentrations, as well as

changes of oxidant (air) flow on the electrical properties of SOFC.

Expected results

The development of new SOFC electrolyte material should allow reducing SOFC operation temperature while maintaining its high efficiency.

Moreover, elaborated regimes of SOFC manufacturing, its testing and operation conditions will be a prerequisite for the creation of power systems

based on SOFCs for a wide variety of applications.

Advantages

Today, the tape-casting technique is considered as the most promising technology for the manufacturing of planar solid oxide fuel cells.

It is the method that guarantees a relatively easy transition from laboratory development to industrial production. The project also focused on

the development of new SOFC electrolyte material.

The improvements of electrolyte material should significantly enhance the efficiency of the entire SOFC.

Competitor

Ceramic Fuel Cell Ltd. (Australia),

Solid Power (Europe),

Julich Research Center (Germany),

Ceres Ltd (UK)

State of development

The method of manufacturing of SOFC electrolyte via the tape-casting technique has been developed. The technique of applying electrodes

(anode and cathode) to the electrolyte and modes of their joint sintering are currently being worked out. The influence of the oxidant flow changes

at a steady stream of hydrogen in argon as a fuel and the change of the flow of hydrogen in argon at a steady stream of oxidant is studied.

The optimal flows of fuel and oxidant were determined; the comparison of the influence of hydrogen in argon and carbon monoxide on the electrical

properties of the SOFC under the same operating conditions are carried out.

Intellectual property

Institute- Executor: Frantsevych Institute for Problems of Materials Science of National Academy of Sciences of Ukraine

Project 18 «Elaboration of tape-casting technique for ceramic fuel cell production»

Tel. +380 44 205 79 76

+380 95 723 15 18

Brodnikovskyi Yehor

Brodnikovskyi Yehor