|

|

On the most important:

|

Science reporting session

|

Abstracts 2011

Abstracts 2012

Abstracts 2013

Abstracts 2014

|

He main directions of development of hydrogen energy (review)

Hydrogen energy: storage and transportation of hydrogen (review)

|

Monograph.

Basic problem of hydrogen energy.

|

|

|

|

|

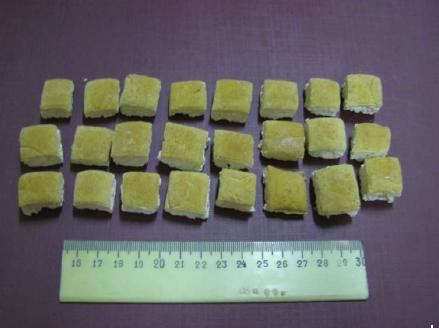

Granular microbial product (GMP) for bio-hydrogen production

Granular microbial product (GMP) for bio-hydrogen production

Area of applications

The current technology is aimed molecular hydrogen production from a wide range of environmentally hazardous multi component organic waste (food waste, agricultural and municipal waste etc.).

Target customer categories are:

1. City administrations;

2. Public catering (restaurants, fast food, cafeteria);

3. Waste management and recycling companies;

4. Food-producing plants;

5. Grocery markets, a network of grocery stores and supermarkets;

6. Companies that have a limited area for waste storage (hotels of resort islands, separated from the waste management infrastructure coastal and mountain resort areas, cruise ships);

7. Agricultural industry.

Brief description

Granulated microbial preparation (GMP) is ready-to-use granular microbial biotechnological product that provides accelerated cost-effective degradation of multi component organic waste accompanied by energy carrier synthesis. Unlike existing microbiological agents aimed at individual household use, GMP is targeted industrial implementation. Due to series of innovations the product use requires minimal number of waste treatment stages, significantly decreases expenses for biotechnology exploitation and characterized by simply integration into existing waste management system.

GMP is the dry light gray or grayish-yellow granules up to 1 cm³. Granules quickly dissolve in aqueous solutions forming component suspension. The product contains microorganisms-destructors of organic polymers, sources of carbon and energy, composition of macro- and trace elements, as well as specific components - regulators of microbial metabolism (RMM), which provide a stable processes, high level of hydrogen production and high efficiency of waste destruction.

Expected results

1. Multifunctioning towards organic waste composition. The use of mixed microbial communities provides the ability to simultaneous digestion of different waste types.

2. Continuous storage period. GMP is manufactured in a form of dry granules with moisture content not exceeding 8%. This results 8 months of storage at least, while for hydrogen-synthesizing communities in the form of culture fluid or biomass it makes 3-7 days.

3. Autonomy. The presence in GMP all the components required for the effective functioning of microbial communities provides its autonomy and simplifies its use.

4. Environmental safety. The product doesn’t contain opportunistic and pathogenic microorganisms. As a result of recycling organic waste opposing to methane fermentation do not form toxic products: ammonia, H2S, SO3, carbon monoxide, etc.

Efficiency parameters:

- - Duration of the destruction cycle - 5-9 days;

- - Destruction rate - reduction of weight and volume of waste by 85-95%;

- - End products: gas mixture of Н2/СО22 containing 35-70% of hydrogen; 5-15% lignin-cellulosic residues (can be used as raw material for the fuel pellets manufacturing);

Biohydrogen yield - 30-190 liters of H2/kg of waste (by absolute dry weight of the substrate);

- Approximate calculations for recycling 1 ton of wet multicomponent organic waste

Average resource consumption: water - 1.5 tons, dry GMP - 30 kg (GMP flow makes 1-5% of the wet waste weight);

Product yield: 20-88 m³ of biohydrogen, 50-150 kg of raw material for fuel pellets manufacturing.

Advantages

Use of GMP offers the customer a new and easy approach to organic wastes treatment allowing:

- Reduction of waste storage volumes and of space necessary for installation of treatment facilities;

- Reduction of expenses for waste transportation and utilization;

- Achievement “zero waste” process;

- Usage of inexpensive and manageable equipment;

- Avoiding certain microbiological and biotechnological operations/facilities;

- To ensure easy control of biotechnological processes;

- Possibility of technology implementation in isolated areas with strong environment protection requirements (recreation areas, cruise ship or Antarctic research station) due to formation of safe and non-toxic products.

Competitors

Industrial analogues of microbial preparations for bio-hydrogen production are not found.

Standard method for processing multi component organic waste is methane fermentation. An alternative to this traditional method can be hydrogen fermentation. Its main advantage is high speed of waste degradation. Average duration for methane fermentation cycle is 30 days, whereas at hydrogen fermentation it takes 5-9 days. Mentioned advantage is significant in condition of rapid waste accumulation and lack of space for their storage. Also the high rate of degradation demand more compact sewage treatment plants comparing to methane fermentation and becomes cost-effective at implementation of technology on an industrial scale.

Project development

4 technologically valuable hydrogen-synthesizing microbial communities are isolated from natural and artificial environments. Optimal methods for microbial biomass production, GMP manufacturing and storing are developed. At the moment experimental line for GMP manufacturing is under development.

Intellectual property

Currently is developing patent strategy to protect intellectual property of the technology (GMP composition, methods of GMP manufacturing and use) for Ukraine and foreign target markets.

Contact information

Executor:

Zabolotny Institute of Microbiology and Virology of the National Academy of Sciences of Ukraine

Project №3 “Development of granulated microbial preparation (GMP) for industrial biotechnologies of molecular hydrogen synthesis during utilization of ecologically dangerous waste”

|

Project leader:

Dr. Oleksandr Tashyrev

Dr. Oleksandr Tashyrev

|

Contact person:

Ph.D. Hanna Tashyreva

Ph.D. Hanna Tashyreva

|

Tel. +38(044)-526 32 97

Е-mail:anna_tach@ukr.net

|

Dr. Oleksandr Tashyrev

Dr. Oleksandr Tashyrev Ph.D. Hanna Tashyreva

Ph.D. Hanna Tashyreva